Recognizing the Trick Parts and Repair Strategies for Packaging Equipment Upkeep

Efficient upkeep of packaging devices hinges on a complete understanding of their key elements, including the structure, drive system, and sealing mechanisms. Identifying typical upkeep concerns, paired with the implementation of preventative techniques and troubleshooting techniques, can significantly boost maker reliability.

Key Components of Packaging Machines

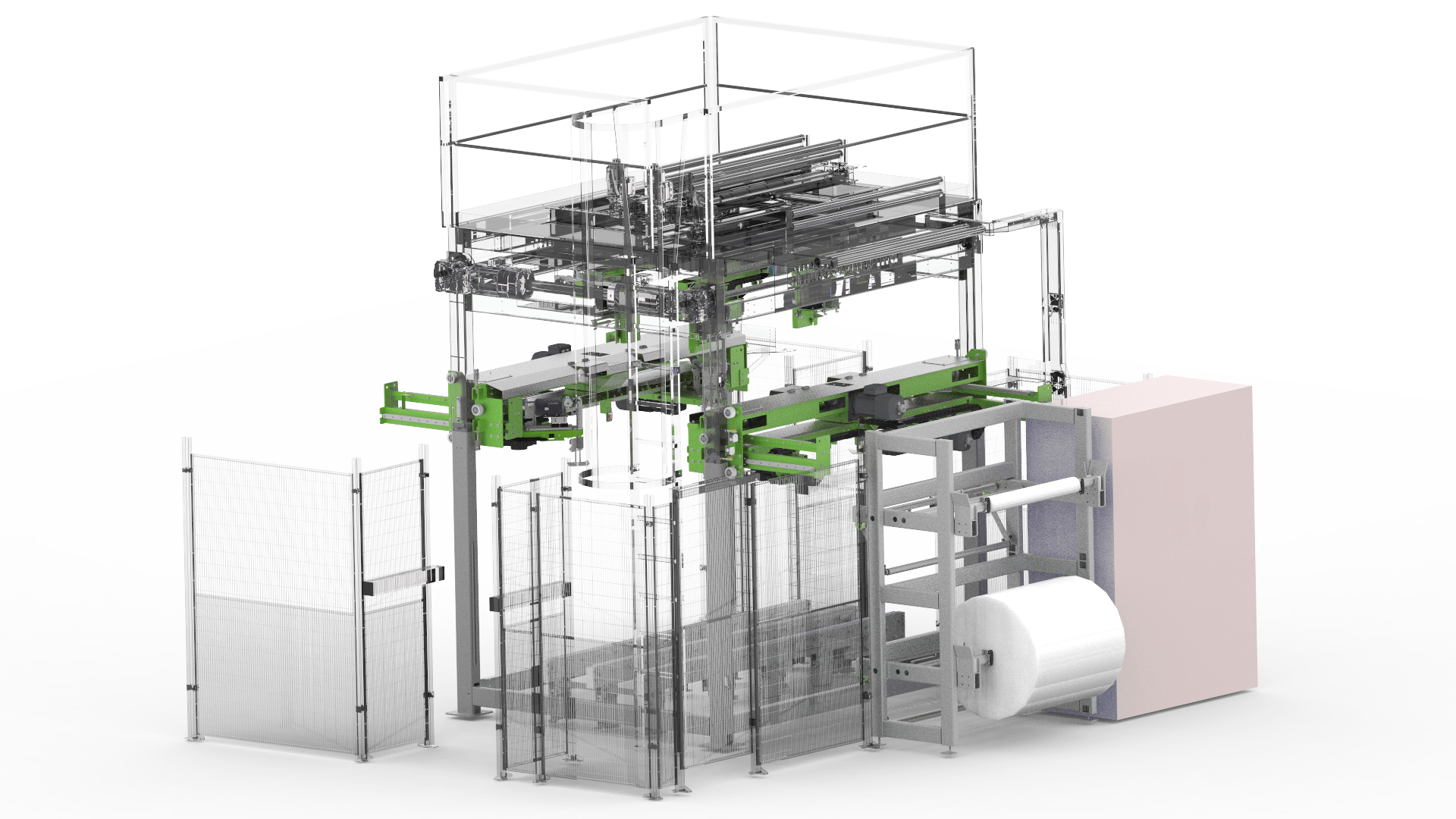

Product packaging equipments consist of several key components that interact to ensure effective and reliable packaging processes. At the core of these machines is the framework, which offers structural integrity and houses the various operating components. The drive system, commonly a combination of equipments and motors, assists in the activity of parts, allowing exact procedure throughout the product packaging cycle.

One more essential element is the conveyor system, which transports products through various phases of the packaging process. This is usually complemented by sensors and controls that keep an eye on the position and rate of products, guaranteeing synchronization and lessening errors. The filling system is critical for properly dispensing the appropriate amount of product into packages, whether in liquid, powder, or solid type.

Securing mechanisms, consisting of warmth sealers or adhesive applicators, play an essential function in safeguarding packages, preventing contamination and prolonging life span. Furthermore, identifying systems are essential for giving essential product details, guaranteeing conformity with policies. The control panel, furnished with user-friendly interfaces, permits operators to manage machine functions, monitor performance, and make changes as needed, making certain optimum performance and efficiency in product packaging operations.

Usual Upkeep Concerns

Effective operation of packaging makers counts greatly on regular maintenance to avoid usual issues that can interrupt production. Among these issues, mechanical damage prevails, especially in components like electric motors, conveyors, and seals, which can result in unforeseen downtimes. In addition, misalignment of parts can result in ineffective procedure, triggering items to be inaccurately packaged or harmed throughout the process.

One more common upkeep issue entails the build-up of dirt and debris, which can hinder the maker's sensors and moving parts. packaging machine repair service. This not just affects performance however can also posture security risks. Lubrication failings can lead to enhanced rubbing, resulting in getting too hot and ultimate part failure.

Electrical problems, frequently stemming from loosened connections or damaged electrical wiring, can disrupt machinery features, leading to substantial production hold-ups. Software application glitches due to inappropriate arrangements or outdated programs can prevent the machine's operation, requiring prompt intervention. Addressing these usual maintenance concerns proactively is essential for guaranteeing optimum efficiency and durability of packaging equipment.

Preventative Upkeep Strategies

Implementing preventative upkeep strategies is vital for sustaining the performance and integrity of product packaging makers. These techniques encompass an organized strategy to maintenance, concentrating on the routine assessment and servicing of tools to preempt prospective failings. By sticking to a scheduled maintenance program, operators can identify damage on elements before they lead to substantial break downs.

Crucial element of a preventative maintenance approach include regular inspections, element, lubrication, and cleansing substitutes based on manufacturer recommendations. Utilizing lists can enhance this process, making certain that no necessary jobs are overlooked. In addition, preserving precise records of upkeep tasks help in tracking the machine's efficiency with time, facilitating informed decision-making relating to future maintenance requirements.

Training personnel on the relevance of preventative maintenance improves conformity and fosters a culture of aggressive care. Executing an anticipating upkeep element, making use of information analytics and sensor technology, can additionally optimize you could check here machinery efficiency by forecasting failures prior to they happen.

Repairing Techniques

When faced with breakdowns or inefficiencies in packaging machines, using methodical troubleshooting methods is essential for determining and solving problems promptly. The primary step in efficient troubleshooting is to establish a clear understanding of the equipment's operational specifications and efficiency metrics. This involves assessing the device's specs, in addition to any mistake informs or codes shown.

Following, operators ought to perform a visual evaluation, looking for obvious indications of wear, damage, or misalignment. This commonly consists of examining gears, belts, and sensors to pinpoint potential reasons for breakdown. Gathering functional information, such as production prices and downtime logs, can additionally offer understandings right into recurring issues.

As soon as potential troubles are recognized, utilizing a logical technique to separate the root reason is important. This may call for testing individual parts or systems in a controlled way. Involving in conversations with drivers that engage with the machinery frequently can generate valuable feedback concerning uncommon actions or patterns.

Repair Service and Replacement Ideal Practices

An extensive understanding of repair and substitute best methods is vital for preserving the long life and performance of product packaging devices. Frequently assessing the condition of maker elements permits prompt intervention, avoiding more significant issues that can result in expensive downtimes.

When repairs are essential, it is necessary to make use of OEM (Original Equipment Supplier) parts to make sure compatibility and efficiency. This not just preserves the honesty of the device yet likewise supports service warranty arrangements. Additionally, it is a good idea to keep an inventory of crucial extra parts to facilitate quick substitutes and reduce functional disturbances.

For complicated repair services, engaging qualified specialists with specialized training in product packaging machinery is advised. They have the expertise to identify problems properly and implement repair services successfully. In addition, documenting all repair service tasks and parts replacements is essential for maintaining an extensive maintenance history, which can aid in future troubleshooting.

Finally, carrying out an aggressive approach, consisting of normal evaluations and predictive maintenance strategies, improves the dependability of packaging makers. By adhering to these finest practices, organizations can make sure ideal machine performance, minimize functional threats, and extend devices lifespan.

Final Thought

Finally, go to the website a complete understanding of product packaging maker elements and effective upkeep strategies is vital for optimal efficiency. Routine inspections and using OEM components can substantially reduce downtime, while a well-documented maintenance background promotes proactive care. Employing qualified technicians additionally boosts repair service top quality and integrity. By applying these techniques, organizations can make sure the durability and effectiveness of packaging makers, inevitably helpful resources contributing to improved operational efficiency and minimized prices.

Efficient maintenance of packaging machines hinges on a complete understanding of their crucial components, including the frame, drive system, and securing mechanisms.Reliable operation of product packaging devices relies greatly on routine upkeep to avoid usual issues that can interfere with manufacturing.Implementing preventative maintenance techniques is critical for sustaining the efficiency and dependability of packaging machines. Additionally, maintaining exact records of upkeep activities help in tracking the device's efficiency over time, helping with notified decision-making pertaining to future maintenance demands.